DOSI-TECH AROMA DOSING

IN-LINE AROMA DOSING SYSTEM FOR FLAVOURED AND FUNCTIONAL WATER

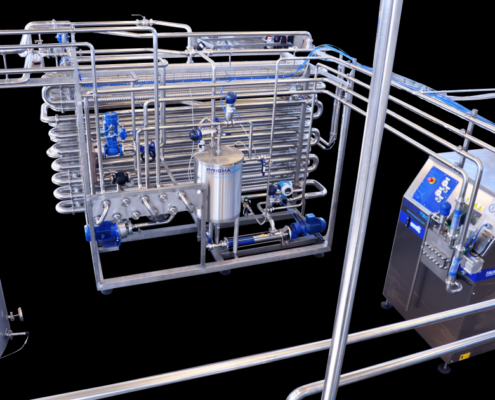

In the production of flavoured and functional waters, PRISMATECH offers a highly space-efficient solution: the inline flavour dosing system. This fully automatic option can be easily integrated into any water production line and is operated via an intuitive control panel, simplifying the process for the operator.

The PRISMATECH inline aroma dosing system is equipped with:

- Dosing pump: this pump sends the liquid from the tank to the water pipe.

- Magnetic flowmeter on the water pipe: this device measures water flow

- Mass flowmeter: this instrument precisely monitors the flow of liquid flavourings.

The two flowmeters send precise signals to the dosing pump, allowing highly accurate and constantly regulated dosing. This system ensures that the exact amount of flavouring is added to the water, guaranteeing the consistency and quality of the finished product.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed to offer high performance and maximum reliability, the PRISMATECH aroma dosing unit is able to meet any space and process requirement, while always ensuring great energy savings.

In every industrial beverage process, PRISMATECH guarantees energy efficiency, preservation of beverage characteristics for a high-quality product, and minimisation of waste.

- AISI 304

- AISI 316L

- FRUIT JUICE

- FLAVOURED WATER

- FUNCTIONAL WATER

- COLD TEA

- DRINKS

- 5 L/H

- 1,000 L/H

- MODULAR

- MONOBLOCK SKID OR MULTIPLE SKIDS

- POSITIONING ON ADJUSTABLE FEET

- CUSTOMISED

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- MASS FLOW METER

- DOSAGE CONTROL

(ON REQUEST)

- MOCA 1935/2004 CE ,FDA

- ATEX

- INDUSTRY 4.0