CARBO-TECH CARBONATOR

WATER AND FINISHED BEVERAGE CARBONATION SYSTEM

PRISMATECH carbonation systems are designed for the production of carbonated water, carbonated soft drinks, wine, non-alcoholic or low-alcohol ready-to-drink (RTD) drinks.

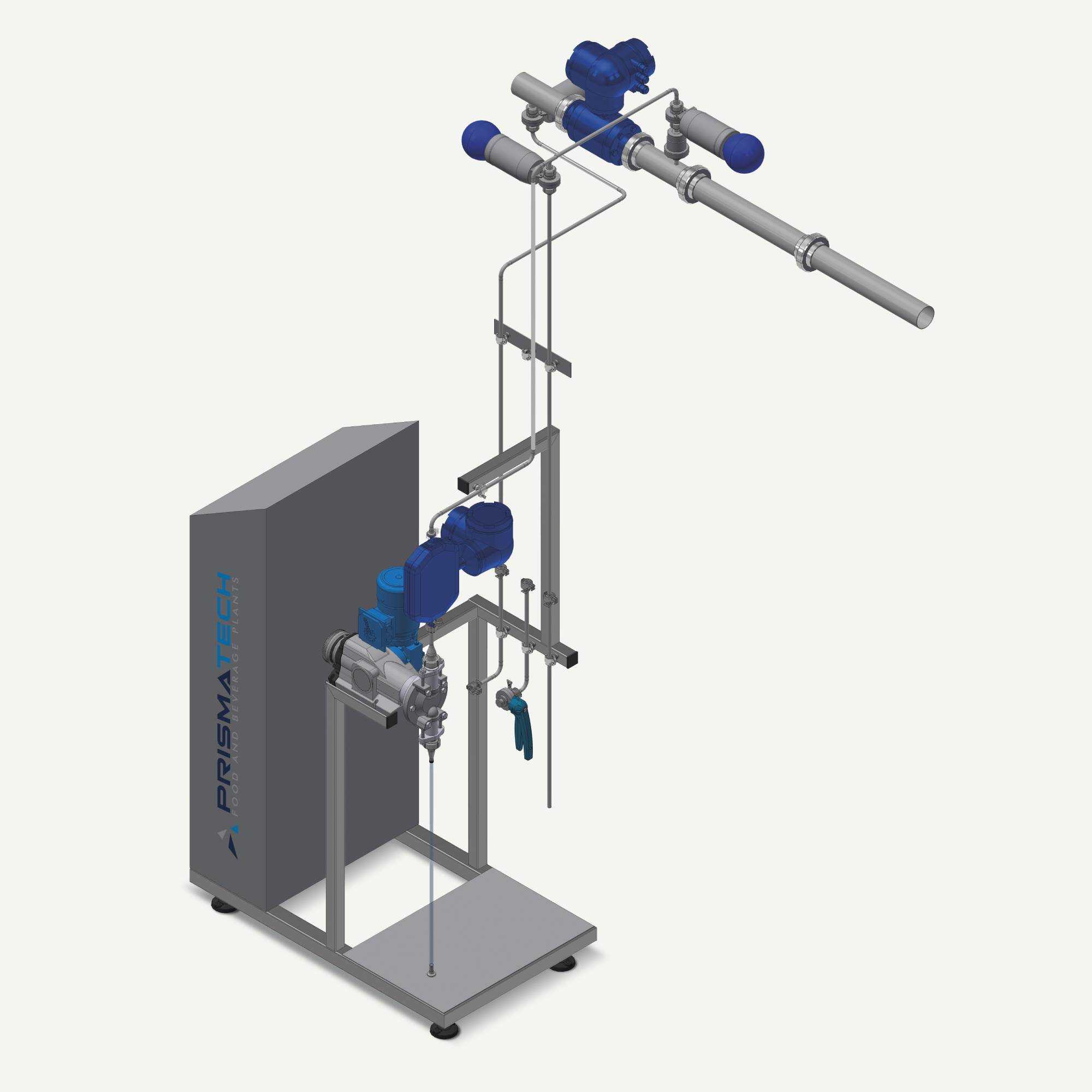

Unlike the MIX-TECH Premix, which is designed for the preparation of made-from-scratch drinks, the CARBO-TECH carbonator, on the other hand, is specialised for the carbonation of finished drinks only.

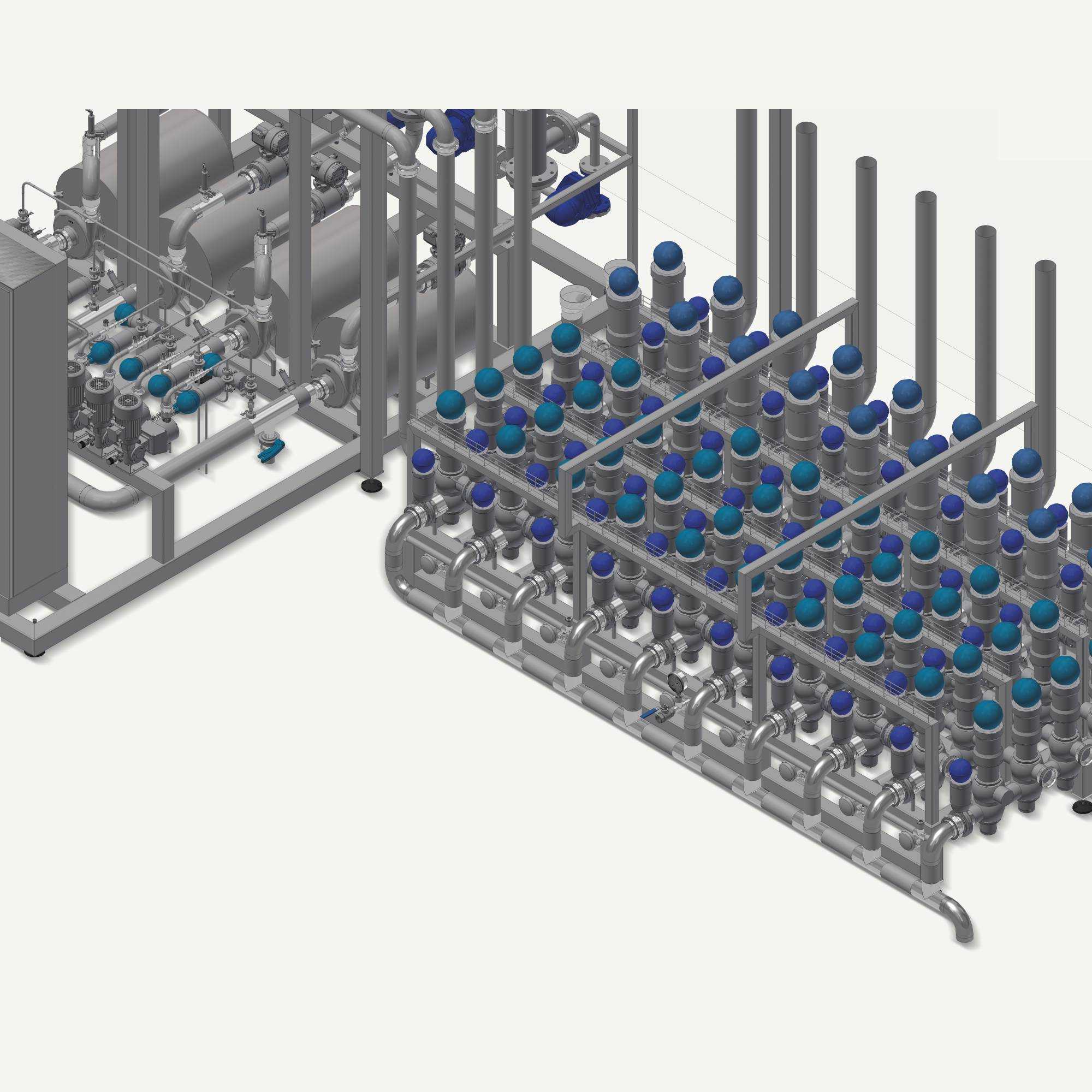

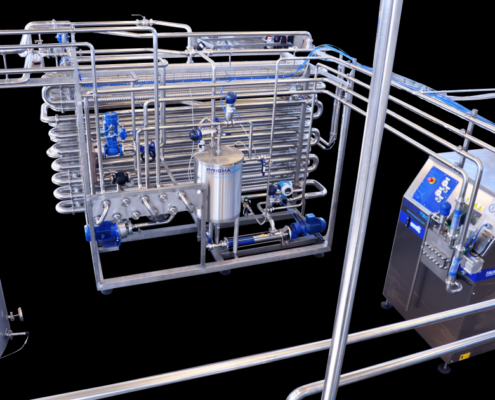

The PRISMATECH carbonator generally consists of a deaeration section, a cooling section, a holding pipe and a stabilisation section for CO2 injection and absorption.

Depending on the level of automation required and the product to be processed, you can configure your carbonator with different options:

Automatic carbonator, equipped with an intuitive HMI control panel with PLC that allows automatic management of all process steps and the various machine components.

Semi-automatic carbonator, for which more operator intervention is required, but without lowering the quality of the product.

1-section carbonator, offered in both automatic and semi-automatic versions and suitable for the production of alcoholic beverages, such as kvass, sparkling wines or pre-mixed cocktails, as no deaeration step is required.

Each solution guarantees a quality product with persistent carbonation, before and after opening.

All PRISMATECH CO2 saturation systems are made of resilient material such as AISI 316L or AISI 304 stainless steel, suitable for food applications.

Possible options for automation upgrades include:

- Automatic CO2 dosing, which allows automatic adjustment of carbon dioxide to ensure a standardised end product based on the g/l predetermined in the recipe

- Inline CO2 analyser for reading carbon dioxide in carbonated soft drinks

- Inline O2 analysis unit for reading the oxygen level in drinks and water

- Inline aroma dosing system for the production of flavoured water

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed for high performance and maximum reliability, PRISMATECH carbonators are able to meet any space and process requirement, always ensuring great energy savings.

In every industrial beverage process, PRISMATECH guarantees energy efficiency, preservation of beverage characteristics for a high-quality product, and minimisation of waste.

- AISI 304

- AISI 316L

- SPARKLING WATER

- FLAVOURED WATER

- CARBONATED SOFT DRINKS

- KVAS

- SPARKLING WINE

- GLASS FILLING

- CAN FILLING

- PET FILLING

- 500 L/H

- 60,000 L/H

- MONOBLOCK SKID

- AUTOMATIC

- SEMI-AUTOMATIC

- ONE-COLUMN

- WATER DOSAGE CONTROL

- CO2 DOSAGE CONTROL

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- AUTOMATIC CO2 DOSAGE

- DEAERATION WITH CO2

- DEAERATION WITH VACUUM

- AROMA SECTION

- COOLER

- MASS FLOW METER FOR WATER

- CO2 ANALYSIS KIT

- O2 RESIDUE ANALYSIS KIT

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0