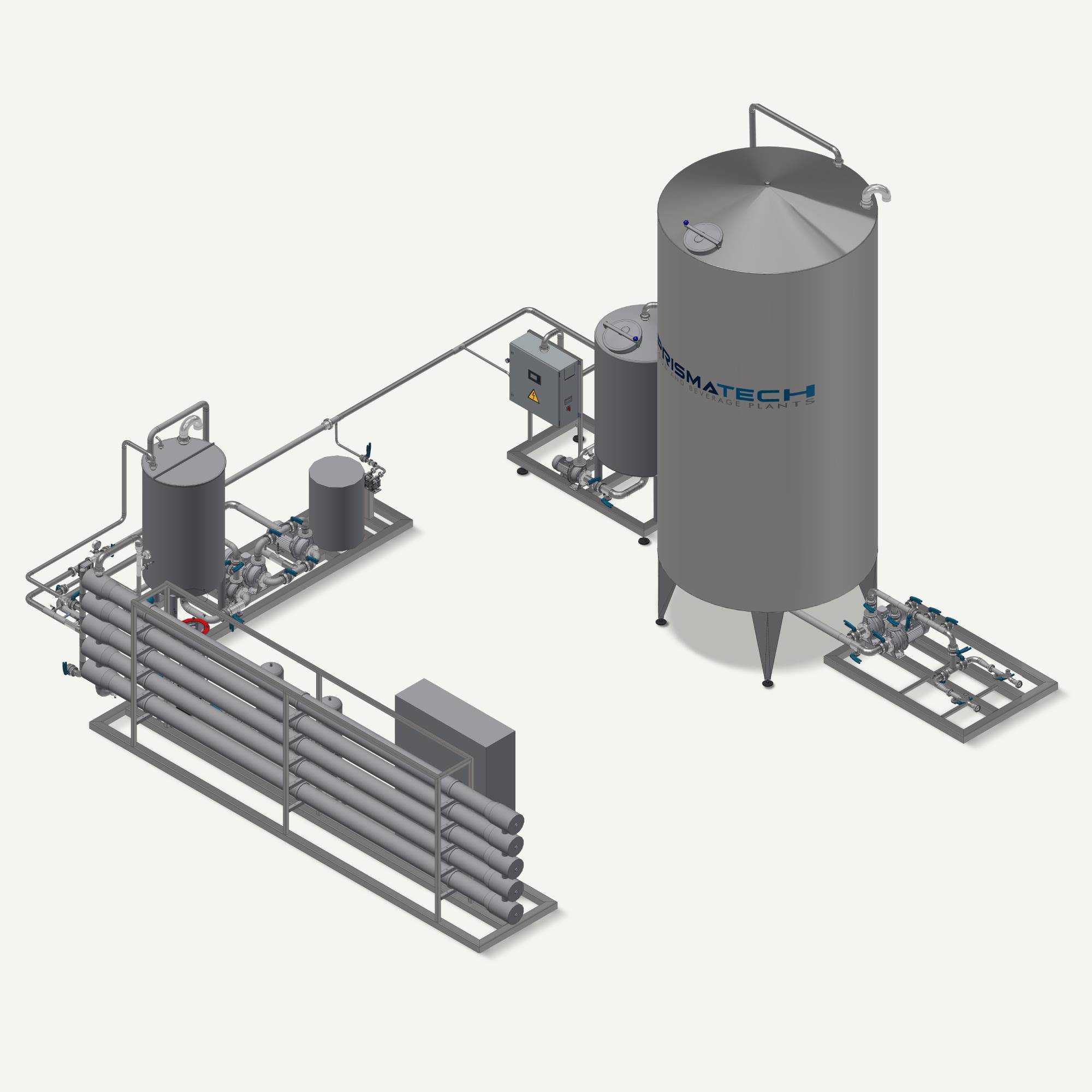

OXY-TECH DEAERATOR

DEAERATION PLANT FOR WATER, JUICES AND CARBONATED DRINKS

Deaeration plays an extremely important role in the production of sparkling water, carbonated soft drinks and fruit juices. This process is essential to reduce the dissolved oxygen content in the drink, thus preparing it for subsequent production steps, such as carbonation in carbonated drinks or pasteurisation in juices.

In the process of preparing beverages, unwanted air and gases can be introduced, compromising their quality, limiting their shelf life and impoverishing their taste.

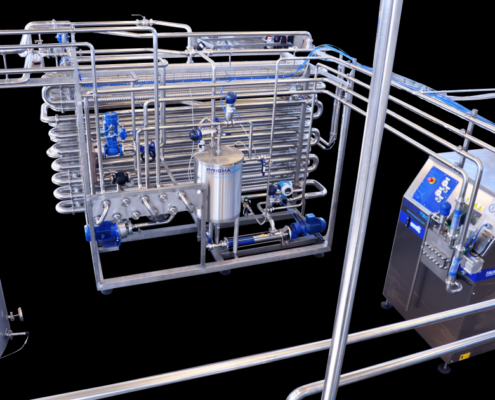

The PRISMATECH Deaerator provides gentle treatment carried out under vacuum conditions and at scrupulously controlled temperatures to ensure maximum protection of the organoleptic qualities of beverages.

In some cases, it may be necessary to implement the deaeration process with an additional vacuum deaeration step (double deaeration or triple deaeration) and/or the ‘gas sparging’ process, which consists of injecting carbon dioxide (CO2).

Deaeration for water and carbonated drinks

When preparing carbonated mineral water and carbonated beverages, it is essential to remove atmospheric air to ensure proper saturation of the product. Neglecting this step could result in the rapid dispersion of CO2, causing loss of effervescence and premature weakening of the carbonated characteristics of the carbonated water or beverage. Integrating deaeration with the cooling phase helps minimise foaming during filling, leading to significant savings and reducing product waste.

Deaeration for fruit juices

For the preparation of fruit juices, the use of deaeration is crucial.

This step prevents oxidation of the ingredients during heat treatment, thus protecting the flavour, appearance and nutritional values of the juice.

PRISMATECH deaerators are designed to minimise the loss of aroma, flavour and volatile components during heating, ensuring the highest quality of the finished product.

SUSTAINABILITY, EFFICIENCY AND CUSTOMISATION

Designed for high performance and maximum reliability, PRISMATECH deaerators are able to meet any space and process requirement, always ensuring great energy savings.

In every industrial beverage process, PRISMATECH guarantees energy efficiency, preservation of beverage characteristics for a high-quality product, and minimisation of waste.

- AISI 304

- AISI316

- FRUIT JUICE

- MINERAL WATER

- FLAVOURED WATER

- ICED TEA

- PUREE

- STILL DRINKS

- GLASS FILLING

- CAN FILLING

- PET FILLING

- BRICK CARTON FILLING

- 200 L/H

- 30,000 L/H (PRODUCT)

- 60,000 L/H (WATER)

- MONOBLOCK SKID

- DEAERATION WITH VACUUM

- DEAERATION WITH CO2

- DOUBLE DEAERATION

- AUTOMATIC

- SEMI-AUTOMATIC

- INDUSTRIAL PC

- PLC AND HMI TOUCHSCREEN

- DATA RECORDING AND ACQUISITION

- USER AUTHENTICATION AND PASSWORD

- REMOTE ASSISTANCE

- ETHERNET COMMUNICATION - PROFINET - WIRED

- PRISMATECH SOFTWARE

- SCADA / FACTORY INTERCONNECTIONS (ON REQUEST)

- COOLER

- PASTEURISER

- HOMOGENISER

- STERILISER

- AROMA RECOVERY

- O2 ANALYSIS KIT

(ON REQUEST)

- MOCA 1935/2004 CE

- FDA

- ATEX

- INDUSTRY 4.0